With this design. borrowed from the past, an unskilled

workforce can erect a simple house in a day. just what they need now

in the Ukraine and in the current earthquake zone

In fact in 1962 I built a 49′ by 12′ concrete shed at the back of

89-90 High Street, Eton, by myself. All you need is a concrete

crusher and a mixer as your machines. Crush rubble, add sand and

cement in our moulds (drawings given free) and you have 1.2M

by 600mm panels which are easily erected – see below

Call me, Colin Hammond on 01386 430 121 for further details

Perfect for Corporate Sponsorship

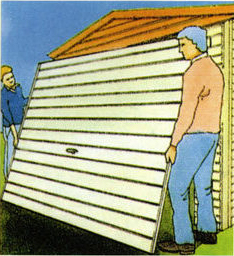

So easy to erect…

Leofric garages are designed with ease of erection in mind. No eperience or special tools are required. The base on which the garage is to stand must be 6″ wider and longer than the external dimensions of the building itself. It must also be flat, level and square and this can be achieved by using shuttering and smoothing the surface of the wet concrete with a flat piece of timber.

Detailed base-laying instructions will be supplied free-of-charge when you order your building. The following sequence gives a brief example of how to erect a typical Leofric garage. Because the concrete sections are heavy the work is best carried out by two people. However, the erection procedure is not difficult and full working instructions are provided with the building itself.

1) Using a piece of chalk, mark the exterior outline of the garage on the base. Begin erecting in a rear corner. Secure a panel into position each side of the corner post using the locking plates supplied.

2) Contiue building until all posts and the bottom two rows of panels are in position on all three sides. (Seal between panels with mastic).

3) Fix the roof trusses to the vertical posts by means of the bolts supplied and then bolt the front fascia into place.

4) Secure remaining wall and window panels into position as before using locking plates provided.

5) Fit roofing sheets (and ridge capping on apex models) by bolting to steel purlins.

6) Bolt the door into position.